The number one in food cooling

Weber Cooling offers the widest range of vacuum coolers for food and kitchens, with the fastest cooling speed, using high-quality technology and offer worldwide service. We are the only supplier to offer specific product lines for different product groups.We have built many vacuum coolers for industrial kitchens, catering and the general food industry around the world. We are known for offering the highest cooling speed vacuum solutions, which is only possible with Hydronic cooling technology!

Our vacuum coolers offer the lowest possible carbon foot print, at an affordable cost.

Benefits for Food & Kitchen

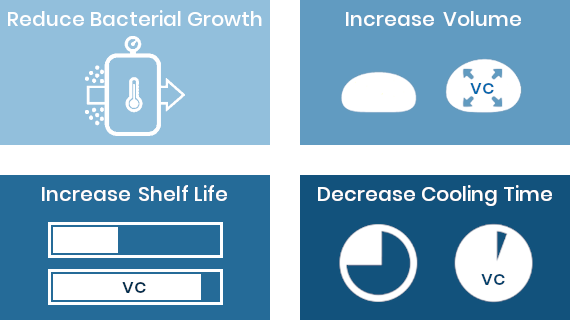

Cooked food in industrial kitchens, (airline) catering & food factories needs to be cooled down before packing & selling. Cooling can take a long time and require high energy costs. Long cooling times will result in reduced shelf life and increased rejects, as bacteria growth is fast, especially at temperatures between 30 – 55 ⁰C (86 – 131 ⁰F). Vacuum cooling is the premium cooling choice over blast air cooling with respect to efficiency, reliability and product quality preservation.- Vacuum cools way faster (15 to 30 min, as compared to hours), using much less space and also saving (50% or more) on electrical energy

- If you put gastronome racks in a vacuum cooler, you are 100% sure ALL food is cooled to the core and desired temperature, as vacuum cools “inside out”.

- As you cool very fast, bacteria get no time to grow, increasing shelf life, reducing reject and preserving quality.

Vacuum Cooling - perfect for cooked food

Vacuum cooling is the fastest & most energy efficient way of cooling for kitchens & food factories. With vacuum most cooked food products can be cooled extremely fast (in only minutes) and homogenous. Besides ultra-fast cooling (at lowest energy cost and with minimum space requirements), vacuum cooling also offers additional advantages (besides longer shelf life and optimal quality preservation) for products like (sushi) rice and bread and bakery. A special range of machinery has been developed for this market.Weber Cooling sets the market standard for Food Vacuum Cooling. No other supplier offers more knowledge on and a wider range of solutions for food vacuum cooling than Weber Cooling!

Practical examples of vacuum cooling of Food

-

Airline Catering

We have recently supplied 12 systems to the Airline industry in the last years, China Eastern, China Southern and Lufthansa are among our customers here. Our vacuum coolers offer unparalleled cost efficiency and performance. No other system will guarantee homogenous cooling – to the core. Of all cooked food! China Northern - China Southern – Lufthansa are three airline companies cooling their in-flight cooked food products with our vacuum coolers – rice & noodles are a main portion of the products cooled. -

Pasta

We have supplied solutions at manufacturers of ingredients for snacks. With vacuum, the pasta can be cooled down to storage temperature within 10 – 15 minutes. Saving on energy costs & cooling time, increasing shelf life and preserving product quality. Lasagna can also be cooled but requires specific precautions while cooling. -

Pastries & Soufflés

Have proven to provide premium taste and strongly increased shelf life when cooled by vacuum. At our bakery experience center, we’re more than able to test also for your application! -

Falafel

Have proven to provide premium taste and strongly increased shelf life when cooled by vacuum. At our bakery experience center, we’re more than able to test also for your application! -

Meat replacers

Based on dairy products can also be cooled perfectly with vacuum. One of the world leaders here is working with our vacuum coolers, to quickly pre-cool their products from production temperatures (around 40 ⁰C or 104 ⁰F) down to below 10 ⁰C or 50 ⁰F. -

Quinoa

Is another product able to cool down fast and efficiently. As with (Sushi) rice, it’s possible to cool down to around 30 ⁰C or 86 ⁰F within around 5 minutes, cooling down to 5 – 10 ⁰C or 40 – 50 ⁰F can be done in around 15 minutes, without problem!